Table of Contents

ToggleWhy Finding the Right Concrete Crack Filler Matters for Texas Homeowners

Cracked concrete is more than an eyesore; it’s a threat to the safety and integrity of your driveways, patios, and foundation. In the Texas Hill Country, where temperature swings and soil movement are common, finding the best concrete slab crack filler is essential for lasting repairs. With over 18 years of local experience, our team provides expert concrete and foundation repair to help homeowners protect their property investment by choosing the right solution.

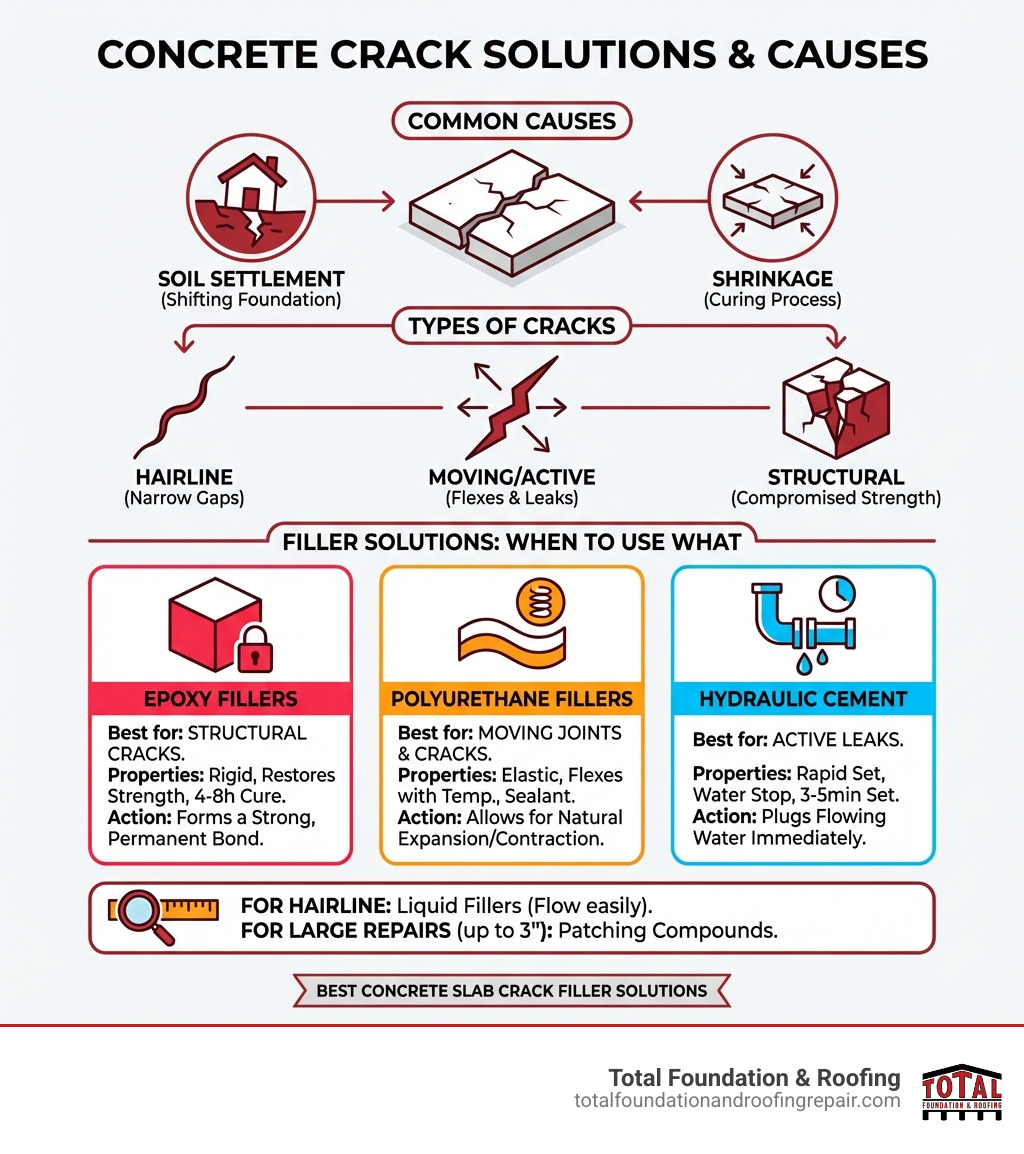

The right filler depends on the crack type, location, and repair goals:

- Structural Cracks: Epoxy-based fillers restore strength.

- Moving Joints: Polyurethane sealants offer flexibility.

- Active Leaks: Hydraulic cement sets in minutes to stop water.

- Hairline Cracks: Liquid fillers penetrate narrow gaps.

- Large Gaps: Patching compounds fill wide voids.

Water is the primary enemy. It seeps into cracks, erodes the base, and expands during freeze-thaw cycles, turning minor issues into major structural problems. Epoxy fillers create a rigid bond to restore strength, while polyurethane fillers flex with temperature changes. Addressing cracks promptly stops water intrusion, prevents further damage, and restores your concrete’s durability. This guide will help you make an informed decision to get your concrete back in top shape.

Relevant articles related to best concrete slab crack filler:

A Guide to the Best Concrete Slab Crack Filler for Every Repair

Choosing the right filler is critical for a durable, long-lasting concrete crack repair. The ideal product depends on the crack’s type, location, and whether it needs rigid strength or flexibility. Understanding the properties of each material is key to selecting the most effective solution.

Best for Structural Strength: Epoxy-Based Fillers

When structural integrity is the priority, epoxy fillers are the top choice. These two-part systems create a bond that is often stronger than the concrete itself, penetrating deep into cracks to restore the slab’s strength. They are ideal for foundations and high-traffic areas.

Key Features of Epoxy Fillers:

- Strength: Creates a high-strength, rigid bond that withstands heavy loads.

- Penetration: Low viscosity allows it to fill fine cracks for a thorough repair.

- Curing: Cures quickly, often reaching full strength in 4-8 hours.

- Drawbacks: Its rigidity makes it unsuitable for moving joints, and it can be more complex and costly to apply.

Application: Epoxy is typically injected into deep cracks or troweled into wider gaps. For serious structural issues, a professional foundation inspection in Kerrville, TX is recommended to assess if an epoxy repair is the right solution.

Best for Flexibility & Movement: Polyurethane Sealants

Polyurethane sealants are champions of flexibility, making them perfect for cracks in driveways, patios, and expansion joints that move with temperature changes. Unlike rigid epoxy, polyurethane accommodates this natural expansion and contraction, preventing re-cracking.

Key Features of Polyurethane Sealants:

- Flexibility: Excellent elasticity accommodates concrete movement.

- Durability: Provides a strong, waterproof, and weather-resistant seal.

- Drawbacks: Curing can take several days, and application is often temperature-sensitive.

Application: Polyurethane comes in two main types:

- Self-leveling: A thin liquid that flows easily to fill cracks on horizontal surfaces like driveways, creating a smooth finish.

- Non-sag: A thicker caulk for vertical or sloped surfaces where it won’t drip or run.

These are ideal for areas with movement, a common issue for expansive soil foundations in Texas. More information on polyurethane sealants highlights their durability.

Best for Active Leaks & Fast Setting: Hydraulic Cement

For active water leaks in basements or foundations, hydraulic cement is the emergency solution. It is engineered to set and harden rapidly, even when in direct contact with water.

Key Features of Hydraulic Cement:

- Fast Setting: Sets in 3-5 minutes to stop water intrusion almost instantly.

- Expansive: Expands as it cures to form a tight, waterproof seal.

- Strength: Creates a very strong, rigid patch.

- Drawbacks: Its rigidity means it’s not for moving cracks, and it requires quick mixing and application.

Application: Mix the powder with water to a putty consistency and press it firmly into the crack. This is a key product for emergency foundation waterproofing and can prevent significant water damage. Technical data on hydraulic cement confirms its rapid solidification properties.

How to Choose and Prepare for the Best Repair

Selecting the best concrete slab crack filler is a decision that impacts the longevity and safety of your concrete surfaces. The American Concrete Institute emphasizes that choosing the right material and preparing the surface correctly are crucial for a lasting repair. Here’s a breakdown of what to consider.

1. Evaluate the Crack:

- Width and Depth: Hairline cracks (<1/8″) need thin, liquid fillers. Medium cracks (up to 1/2″) can use pourable fillers or caulks. Large cracks (>1/2″) require patching compounds or polyurethane sealants designed for wide gaps, sometimes with a backer rod for support.

- Surface Orientation: Use self-leveling fillers for horizontal surfaces (driveways, patios) and non-sag fillers for vertical surfaces (walls, steps) to prevent dripping.

2. Consider Environmental Factors:

- Movement: For cracks that expand and contract (e.g., expansion joints), a flexible polyurethane sealant is essential.

- Weather: In Texas, fillers must withstand UV exposure and freeze-thaw cycles. Polyurethane offers excellent weather resistance.

- Water: For active leaks, use hydraulic cement. For general waterproofing, polyurethane is a great choice.

3. Plan for Application and Curing:

- Curing Time: Hydraulic cement sets in minutes. Epoxies cure in hours. Polyurethanes can take several days to fully cure. Plan for downtime accordingly.

- Aesthetics: If you plan to paint the repair, check if the filler is paintable. Many latex and polyurethane products are.

| Filler Type | Strength | Flexibility | Cure Time (Initial/Full) | Best Use |

|---|---|---|---|---|

| Epoxy | Very High | Low | 4-8 hours / ~24 hours | Structural cracks, foundation repair |

| Polyurethane | High | High | Few hours / 3-7 days | Moving cracks, expansion joints |

| Hydraulic Cement | High | Very Low (rigid) | 3-5 mins / 28 days | Stopping active water leaks |

| Masonry Mortar | Moderate | Low | 24-48 hours / 28 days | Large, non-structural gaps |

| Latex-based | Low to Moderate | Moderate | 24 hours / Few days | Hairline cracks, easy cleanup |

For a detailed breakdown of project costs, see our concrete repair cost guide.

4. Prepare the Surface for a Strong Bond:

Proper preparation is a non-negotiable step detailed in our guide to patching cracks in concrete.

- Clean: Use a wire brush and pressure washer to remove all dirt, grease, and loose debris from the crack.

- Widen: For narrow cracks, use a chisel to create a “V” shape for better filler adhesion.

- Dry: Ensure the surface is completely dry, as most fillers fail on damp concrete.

- Back-fill: For deep cracks, use a backer rod or sand to save material and ensure a proper seal.

- Temperature: Apply fillers within the manufacturer’s recommended temperature range.

Professional Repair and Long-Term Concrete Maintenance

While many small cracks are suitable for a DIY project, significant damage requires an expert. Knowing when to call a professional can prevent costly, catastrophic failures.

When to Call a Professional for Concrete Slab Repair

You should seek professional help if you observe:

- Large Structural Cracks: Cracks wider than ½ inch, deep, or running through the entire slab.

- Foundation Settlement: Signs like uneven floors, sticking doors, or cracks spreading up walls.

- Heaving Concrete: Sections of concrete pushed upwards, creating trip hazards. This may require concrete leveling or concrete lifting.

- Spreading Cracks: A network of interconnected cracks that are actively growing.

- Persistent Water Leaks: Active leaks that suggest deeper drainage or foundation issues.

At Total Foundation & Roofing, we specialize in expert assessment and lasting concrete crack solutions for the unique soil and climate of the Texas Hill Country. Our certified concrete contractor team provides comprehensive foundation repair services in Kerrville and the surrounding area. For a complete evaluation of your concrete and foundation needs, contact our team for a free estimate.

Best Practices for Maintaining Concrete Surfaces to Prevent Future Cracks

Proactive maintenance is key to preventing future cracks and extending the life of your concrete.

- Regular Cleaning: Keep surfaces free of dirt and debris to prevent moisture buildup.

- Sealing Your Concrete: Apply a quality sealer every 2-3 years to protect against moisture and freeze-thaw damage.

- Ensure Proper Drainage: Direct water away from slabs and foundations with proper grading, gutters, and downspouts.

- Avoid Harsh Chemicals: Use sand for traction in winter instead of deicing salts that can damage concrete.

- Inspect Regularly: Catching small cracks or spalling early prevents them from becoming major problems.

DIY vs. Professional Grade Products

The right product often depends on the complexity of the repair and your experience level.

DIY-Friendly Products:

- Liquid Fillers & Premixed Patches: Easy to apply for hairline cracks and non-structural patching.

- Caulk-Gun Sealants: Polyurethane sealants in caulk tubes are accessible for most homeowners and great for joints and medium cracks.

Professional or Advanced DIY Products:

- Epoxy Injection Kits: Best for structural foundation cracks, these require precision and specialized tools.

- Two-Part Epoxies: Offer superior strength but require accurate mixing and have a short working time.

- Hydraulic Cement: While simple to mix, effectively stopping a high-pressure leak requires experience.

When in doubt, especially with foundation issues or large, spreading cracks, consulting a professional is the safest choice. An expert can correctly diagnose the problem and recommend the best concrete slab crack filler or repair method for a durable, safe result.