Table of Contents

ToggleWhy Choosing the Right Crack Filler Matters for Your Property

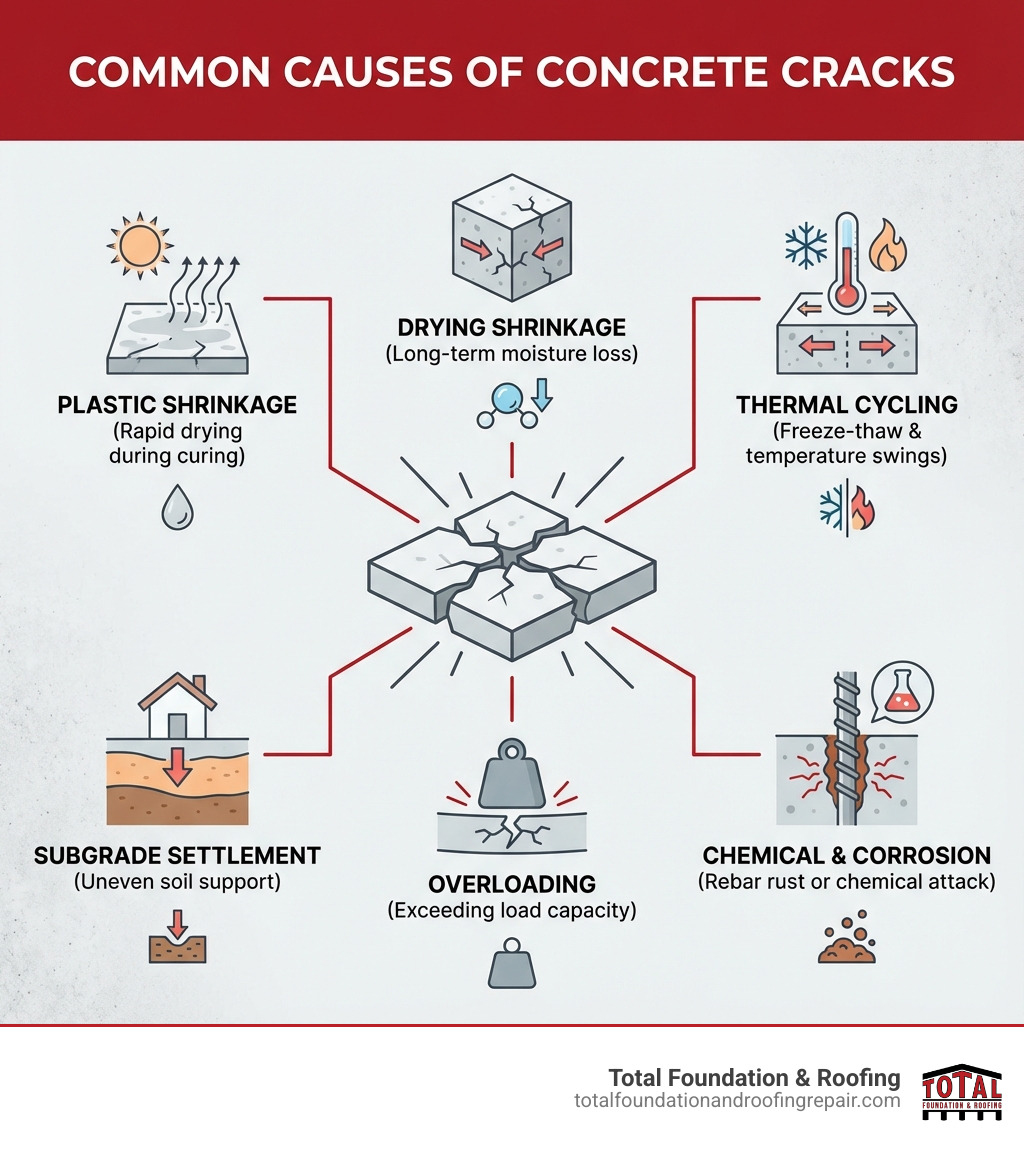

Cracks in exposed aggregate concrete are more than an eyesore; they are gateways for water intrusion, freeze-thaw damage, and progressive deterioration. For any significant issues, professional concrete repair is the best course of action, as traditional patches often create color mismatches and fail to bond properly. The best aggregate crack filler options vary based on your specific needs.

Here’s what performs best for different situations:

| Crack Type | Best Filler Type | Key Benefit |

|---|---|---|

| Hairline (<1/8″) | Liquid cement or thin caulk | Flows easily into narrow gaps |

| Medium (1/8″-1/2″) | Self-leveling polyurethane sealant | Flexible and weather-resistant |

| Wide (>1/2″) | Cement-based patch or epoxy | Structural strength and durability |

| Exposed Aggregate | Clear polyurethane or color-matched cement | Maintains aesthetic appearance |

Selecting a product designed for aggregate surfaces ensures both durability and a seamless finish. For Texas homeowners in the Hill Country, where temperature swings accelerate concrete degradation, choosing a filler with flexibility and weather resistance is critical.

As Daniel Sowell, owner of Total Foundation & Roofing Repair with over 18 years of experience in the Texas Hill Country, I’ve seen many DIY repairs fail due to the wrong product choice. Understanding which fillers work for different crack types, locations, and conditions is the key to a successful, long-lasting repair.

Best aggregate crack filler terms simplified:

Understanding and Choosing the Best Aggregate Crack Filler

When faced with a cracked concrete surface, understanding the crack and the right material is the first step. For exposed aggregate concrete, with its unique aesthetic, this is especially true. The three primary types of aggregate crack fillers are epoxy, polyurethane, and cement-based, each with distinct properties.

Material Breakdown: Epoxy, Polyurethane, and Cement-Based

The best aggregate crack filler depends on its chemical composition and intended use.

Epoxy Fillers: Known for exceptional strength, epoxy fillers create a bond often stronger than the concrete itself. They are waterproof and cure quickly, making them ideal for structural repairs where a rigid bond is needed. However, their rigidity makes them less suitable for areas with significant temperature-driven movement.

Polyurethane Fillers: For superior flexibility and weather resistance, polyurethane is the top choice. Concrete expands and contracts, especially in the Texas Hill Country. Polyurethane’s elasticity allows it to move with the concrete, preventing new cracks. Self-leveling sealants are easy to apply on horizontal surfaces, while non-sag options are perfect for vertical applications or areas with extreme temperature shifts.

Cement-Based Fillers: These are used for their textured finish that can blend with existing concrete. Hydraulic cement, a specific type, is highly effective for stopping active water leaks, setting in just 3-5 minutes. While strong, they lack the flexibility of polyurethane, making them less ideal for cracks that experience movement. For more details, explore our guide on concrete repair methods.

The Best Aggregate Crack Filler for Your Crack Size

Choosing the right filler also depends on the crack’s size.

Hairline Cracks (<1/8″): Liquid fillers or thin caulks are best, as their low viscosity allows them to penetrate narrow gaps.

Self-Leveling vs. Non-Sag Fillers: This is a key distinction. Self-leveling fillers are for horizontal surfaces (driveways, patios), flowing easily to create a smooth finish. Non-sag fillers are thicker, designed for vertical surfaces (walls) where you need the material to stay in place without dripping.

Wide/Deep Cracks (>1/2″): These require more substantial solutions like cement patches or thicker epoxies. For very deep cracks, a foam backer rod should be inserted first to control the filler depth and improve the repair’s longevity. Our complete guide to concrete crack repair offers more detailed techniques.

Special Considerations: Location, Weather, and Cost

Finally, consider the crack’s location, local weather, and your budget.

Location Matters: Driveways need high traffic resistance. Patios prioritize aesthetics. For foundations, waterproofing is non-negotiable. While hydraulic cement is excellent for minor basement leaks, significant foundation issues require professional help. Repairing cracks in concrete foundation is a specialized task where the right material is paramount.

Weather Resistance: In the Texas Hill Country, fillers must withstand temperature swings and UV exposure. Polyurethane’s flexibility makes it a robust choice for our climate, preventing water intrusion that accelerates deterioration.

Cost Implications: While it’s tempting to choose the cheapest option, a failed repair costs more in the long run. Consider long-term value over upfront price. You can learn more about typical foundation crack repair costs to help budget.

Exposed Aggregate Specifics: The goal is a seamless blend. Specialized products are designed to match the texture and color of exposed aggregate, preserving its unique appearance.

Application Guide: Achieving a Professional, Long-Lasting Repair

Even the best aggregate crack filler won’t perform without proper application. A successful repair hinges on correct surface preparation and technique.

The Best Aggregate Crack Filler Application Process: A Step-by-Step Guide

Applying aggregate crack filler is a meticulous process.

Surface Preparation (The Most Crucial Step!): A clean, dry surface is vital for proper adhesion. Use a wire brush or pressure washer to remove all loose debris, dirt, and vegetation. Allow the concrete to dry completely (at least 24 hours) before applying filler, as moisture can compromise the bond. Before you begin, always read the Safety Data Sheet for your chosen product.

Tools Needed: Gather a caulk gun (for cartridges), a putty knife or trowel, safety glasses, and gloves. For deep cracks, you will also need a backer rod.

Application: Firmly push the filler into the crack, ensuring it fills from the bottom up. For non-sag fillers, tool the joint immediately for a smooth finish. Self-leveling products typically do not require tooling.

Curing Time: Curing times vary dramatically, from minutes for hydraulic cement to several days for some polyurethane sealants. Always check the product’s instructions for dry times and when the area is ready for foot or vehicle traffic.

Pro Tips for a Flawless Finish

For a durable and aesthetically pleasing repair, follow these best practices.

Aesthetic Matching: To blend the repair on exposed aggregate, you can sprinkle matching loose aggregate onto the wet filler. Alternatively, using a colored concrete crack filler designed to match your surface is a game-changer. Always test on a small, inconspicuous area first.

Sealing the Repair: Once the filler has cured, sealing the area protects it from UV degradation and moisture, ensuring longevity. Refer to the product’s Technical Data Sheet for specific sealing recommendations.

When to Call the Experts for Concrete Repair

While many small cracks are a manageable DIY project, certain signs indicate it’s time to call a professional.

Signs of Structural Issues: Call an expert if you see wide, moving cracks; uneven or sunken slabs; or cracks caused by drainage issues. Buckled or lifted concrete also requires professional assessment.

When DIY is Not Enough: If you’re dealing with extensive cracking or feel overwhelmed, our expertise is invaluable. Total Foundation & Roofing has deep experience with concrete and foundation issues specific to the Texas Hill Country, serving areas like Kerrville, TX. We understand the unique challenges our local climate and soil present.

For a professional assessment and expert crack repair services, don’t hesitate to reach out. We’re here to ensure your concrete surfaces are safe, durable, and aesthetically pleasing.