Table of Contents

ToggleWhy Concrete Lifting is Your Best Solution for Sunken Slabs

Concrete lifting is a repair method that raises sunken concrete slabs by injecting material underneath to fill voids and restore the surface to its original level. Here’s what you need to know:

What it is: A process of drilling small holes and pumping lifting compounds beneath settled concrete

How it works: Material expands or hardens to lift the slab back into position

Cost savings: Up to 70% less expensive than concrete replacement

Timeline: Most repairs completed in hours, not days

Best for: Driveways, sidewalks, patios, garage floors, and pool decks with minor to moderate settling

If you have a sunken driveway, patio, or walkway, you know the frustration and safety risks it can cause. Thankfully, complete replacement isn’t your only option. Concrete lifting offers a faster, more affordable solution that can restore your property’s safety and appearance without the mess and expense of tearing out existing concrete. For Texas homeowners dealing with shifting soils and settlement issues, professional foundation and concrete repair experts provide the expertise needed for lasting repairs, often in just a few hours.

Instead of waiting weeks for a replacement project, your lifted concrete can be ready for use within 24 hours. I’m Daniel Sowell, owner of Total Foundation & Roofing Repair with over 18 years of experience in foundation and concrete work throughout the Texas Hill Country. I’ve helped countless homeowners solve their concrete lifting challenges using proven methods that deliver long-lasting results.

Concrete lifting terms to learn:

What Causes Concrete to Settle?

Before we dive into how concrete lifting works, it’s crucial to understand why concrete settles in the first place. Think of concrete slabs like a heavy table – they’re only as stable as what’s supporting them underneath. When the soil beneath your concrete weakens or shifts, that “table” starts to sink, creating those frustrating uneven surfaces and dangerous trip hazards you’re dealing with.

The truth is, concrete settlement is incredibly common here in the Texas Hill Country. Our unique soil conditions, combined with dramatic weather changes, create the perfect storm for sinking slabs. Understanding what’s happening beneath your concrete is the first step toward choosing the right repair method and ensuring it lasts for years to come.

Common Culprits Behind Sunken Slabs

Soil expansion and contraction is by far the biggest troublemaker in our area. Texas clay soil acts like a giant sponge – it swells dramatically when it gets wet during our intense summer storms, then shrinks back down during dry spells. This constant cycle of growing and shrinking creates gaps and voids under concrete slabs, leaving them without proper support.

Water damage and erosion work hand-in-hand to wash away the soil that should be supporting your concrete. Poor drainage around your property sends rainwater straight under your slabs, where it slowly but surely carries away the supporting soil. If you’ve noticed water pooling near your sunken concrete, this is likely your culprit.

Uncompacted backfill is a hidden problem that shows up years after construction. When builders excavate around foundations and then fill the area back in, that soil needs to be properly compacted. If it wasn’t, it will gradually settle over time, taking your concrete with it. This is especially common around newer homes where the soil hasn’t had time to naturally settle.

Heavy loads can overwhelm concrete that wasn’t designed to handle the weight. Your driveway might be fine supporting your car, but struggle when that concrete delivery truck parks on it. Over time, these excessive loads create cracks and settlement that professional foundation and concrete services can address with concrete lifting techniques.

Tree roots create a unique problem – they might initially lift your concrete as they grow, but when those roots decay or the tree is removed, they leave behind voids that cause settlement. Time and gravity are also constantly at work, as even properly installed concrete can settle slightly over the years due to natural soil consolidation.

Here in areas like Kerrville, Fredericksburg, and Comfort, we also deal with filled-in land where previous construction or natural settling has left less stable soil conditions. Seismic activity, while minor in Texas, can contribute to gradual soil shifting over many years.

The key to successful concrete lifting is identifying which of these factors caused your specific settlement problem. This helps us choose the right lifting method and address any underlying issues to prevent future problems.

How Professional Concrete Lifting Works: A Step-by-Step Guide

When you watch a professional concrete lifting team at work, you’ll be amazed at how straightforward the process actually is. What seems like magic – watching heavy concrete slabs rise back to their proper level – is really just good engineering and the right equipment in skilled hands.

Professional concrete leveling services use a systematic approach that transforms your sunken, uneven surfaces into smooth, safe walkways and driveways. The entire process causes minimal disruption to your daily routine, and you’ll be walking or driving on your repaired concrete in no time.

The Three-Step Lifting Process

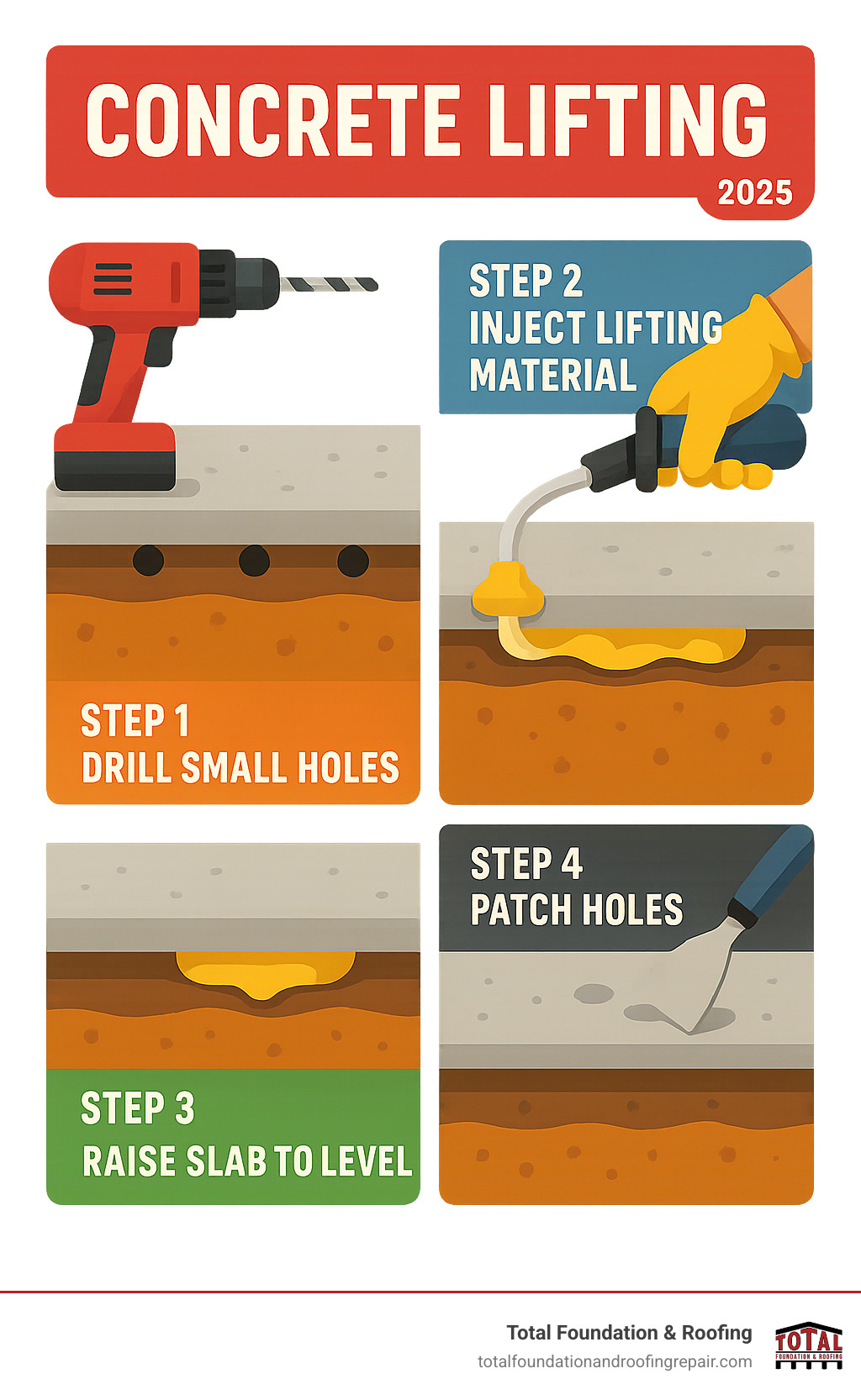

Step one involves drilling strategic holes in your sunken concrete slab. These aren’t random spots – our technicians carefully choose locations that will provide the best lift and even weight distribution. Depending on the lifting method we’re using, these holes range from tiny ⅝-inch openings for polyurethane foam up to 2-inch holes for traditional mudjacking materials.

The second step is where the real action happens. We pump the lifting compound through these access holes, directly into the empty spaces beneath your concrete. As the material fills these voids, it creates pressure that gently pushes your slab back up to where it belongs. This isn’t a violent process – we control every bit of the lift to ensure your concrete moves smoothly and evenly.

Finally, we seal everything up by patching those drill holes with specially matched grout or cement. We take pride in making these repairs blend seamlessly with your existing concrete. You’d be surprised how invisible these patches become once we’re finished with color-matching materials.

The beauty of this controlled process is that there’s no jackhammering, no hauling away broken concrete, and no waiting weeks for new concrete to cure. Your property stays clean, and the disruption to your routine is minimal.

How Long Does the Process Take?

Here’s one of the best parts about concrete lifting – most jobs wrap up in just a few hours. A typical driveway section or small patio might take us 2 to 4 hours from setup to cleanup. Even larger projects like extensive garage floors or multiple sections of pool decking usually finish within 1 to 3 days.

But the real time-saver comes after we’re done. Unlike concrete replacement, which involves days of demolition, pouring, and then waiting several more days for curing, your lifted concrete is ready for use almost immediately. With polyurethane foam, you can literally walk on it as soon as we pack up our equipment. Stone slurry grout needs about 24 hours for the drill holes to fully cure, but that’s still incredibly fast compared to replacement.

Think about it this way – while your neighbor waits two weeks for their concrete replacement project to finish, you’re already back to using your driveway or patio the same day we visit. That’s the kind of quick turnaround that makes concrete lifting such a practical solution for busy homeowners.

Comparing the Types of Concrete Lifting

When it comes to concrete lifting, choosing the right method can make all the difference between a repair that lasts decades and one that needs redoing in a few years. Think of it like choosing the right tool for a job – you wouldn’t use a hammer when you need a screwdriver, right?

At Total Foundation & Roofing, we’ve seen how different methods work in various situations across the Texas Hill Country. The best approach for your specific situation depends on several factors: your budget, the type of concrete, the underlying soil conditions, and how quickly you need to use the area again.

Here’s how the three main professional concrete lifting methods stack up against each other:

| Feature | Polyurethane Foam Lifting | Stone Slurry Grout Leveling | Mudjacking (Traditional) |

|---|---|---|---|

| Hole Size | ⅝ inches (smallest) | 1 inch | 1-2 inches (typically 2 inches, largest) |

| Material | Two-part expanding polymer foam | Pulverized limestone, water (+ Portland cement) | Topsoil, Portland cements, sand, water, additives |

| Weight | Lightweight, minimal added load | Heavier than foam, lighter than mudjacking | Heaviest, significant added load |

| Strength | High (6,000 lbs/sq ft baseline, up to 125 tons in 900 sq ft) | Very High (240 psi, 6,000+ psi w/ cement) | High (can be improved with Portland cement) |

| Cure Time | Fast (minutes, 90% strength in 15 min) | Slower (hours to days) | Slow (days) |

| Cost | Highest (20-50% more than stone slurry) | Mid-range | Lowest (10% less than stone slurry) |

| Environmental Impact | 39-49% renewable/recycled materials | Environmentally friendly (natural material) | Environmentally friendly (natural material) |

| Water Resistance | Impervious to water, moisture-tolerant | Less resistant to erosion than foam | Prone to erosion, can wash away |

| Warranty | Generally longer | Standard | Shorter (typically 2-3 years) |

Polyurethane Foam Concrete Lifting: The Modern Approach

If concrete lifting methods were cars, polyurethane foam would be the sleek sports car – fast, precise, and packed with the latest technology. This method has revolutionized how we approach sunken concrete repairs.

Here’s how it works: We inject a two-part polymer foam beneath your concrete through tiny ⅝-inch holes – about the size of a pencil. The foam rapidly expands to fill voids, then hardens within minutes. It’s like watching magic happen, but it’s actually precise engineering at work.

The strength of this material is impressive. Some closed-cell polymer foams can handle 6,000 pounds per square foot right off the bat, and we’ve seen loads as heavy as 125 tons lifted and stabilized in areas smaller than 900 square feet. For technical folks who want to dive deeper, check out this resource on Slab Jacking With Polyurethane Foam – How Strong is Strong Enough?.

The speed is what really sets foam apart. Your concrete can be ready for foot traffic in minutes and vehicle traffic often in less than an hour. Compare that to waiting days for traditional methods to cure, and you can see why busy homeowners love this option.

Environmental considerations are important too. Modern geotechnical foams often contain 39-49% renewable and recycled materials, making them more eco-friendly than you might expect. Plus, since the material is waterproof, it helps prevent future water damage and erosion.

What makes foam great: The smallest drill holes mean repairs are virtually invisible, it’s lightweight so it won’t stress weak soils, the waterproof nature prevents future problems, and it can actually stabilize loose soil beneath your slab.

The trade-offs: It costs more – typically 20-50% higher than other methods. It also requires specialized equipment and training, so not every contractor can do it properly. There’s also some heat generated during the expansion process, though this isn’t usually a problem with professional application.

Stone Slurry Grout Leveling

Stone slurry grout leveling strikes a nice balance between performance and cost. Think of it as the reliable pickup truck of concrete lifting methods – it gets the job done well without breaking the bank.

This method uses pulverized limestone mixed with water, and often Portland cement for extra strength. We pump this mixture through 1-inch holes into the voids beneath your concrete. The limestone is completely natural, making this one of the most environmentally friendly options available.

When Portland cement is added to the mix, the compressive strength jumps dramatically from 240 pounds per square inch to over 6,000 psi. That’s serious lifting power that provides excellent long-term support for your concrete.

Why homeowners choose stone slurry: It’s budget-friendly compared to foam, uses natural materials that won’t harm the environment, provides excellent strength especially with cement additives, and allows for precise lifting control.

Things to consider: The material takes longer to cure than foam, so you’ll need to wait longer before using the concrete. It can be slightly messier than foam (though still much cleaner than replacement), and while it’s more erosion-resistant than traditional mudjacking, it’s not completely waterproof like foam.

Mudjacking: The Traditional Method

Mudjacking is the grandfather of concrete lifting methods, and like many tried-and-true approaches, it’s still around because it works. This method has been successfully raising sunken concrete for over a century.

The process involves pumping a mixture of topsoil, Portland cement, sand, water, and additives through 2-inch holes. Yes, the holes are larger and more noticeable, but the method is proven and reliable. For detailed information about the material properties, you can review Advantages of Mud-Jacking Grout for Use in Slab Leveling.

The biggest advantage is cost – mudjacking is typically about 10% less expensive than stone slurry grout leveling, making it the most budget-friendly option. It uses completely natural, readily available materials, and the low-pressure application allows for careful, controlled lifting.

The considerations: The 2-inch holes are more noticeable after repair, the material is heavier which can be problematic on very weak soils, and it generally requires more cleanup. The material is also more susceptible to washing away over time if drainage problems persist, which is why warranties are typically shorter (2-3 years) compared to other methods.

The cure time is slower than foam, and the overall process takes longer from start to finish. However, for homeowners who prioritize cost savings and don’t mind waiting a bit longer for the concrete to cure, mudjacking remains an excellent choice.

Is Lifting Right for You? Cost, Timing, and Limitations

Understanding when concrete lifting is the best fit for your situation is crucial for a successful project. While this repair method can save you up to 70% compared to replacement, it’s not a magic solution for every concrete problem. Think of it like choosing the right tool for the job – concrete lifting is incredibly effective for specific situations, but knowing when to use it makes all the difference.

The investment in professional concrete leveling services varies based on several factors, and understanding these costs helps you make an informed decision. To learn more about the factors that determine the final price for this service, explore our detailed guide on Concrete Lifting Cost.

In our Texas Hill Country region, we typically see these price ranges for common concrete lifting projects:

Sidewalk repairs run $750 to $2,400, while garage floor leveling ranges from $900 to $4,500. Porch concrete lifting costs between $1,200 and $6,000, and pool deck repairs fall between $1,500 and $4,400. Driveway leveling typically costs $900 to $4,200, step repairs range from $990 to $2,400, and patio leveling runs $900 to $3,500. For interior floor slabs, expect $1,400 to $6,000, while AC pad leveling is more affordable at $650 to $1,400.

Most concrete lifting companies have minimum starting prices ranging from $400 to $1,500. The final cost depends on the total square footage, how much lift is needed, job complexity (like existing cracks or required saw cutting), and your chosen material. Polyurethane foam typically costs 20-50% more than stone slurry leveling, while mudjacking runs about 10% less than stone slurry.

When to Consider Concrete Lifting

Concrete lifting shines when addressing settlement that creates safety hazards, drainage problems, or detracts from your property’s appearance. It’s particularly effective for sunken sidewalks where trip hazards pose safety risks and ADA compliance concerns. Uneven driveways benefit greatly from leveling, restoring smooth surfaces while preventing vehicle damage and improving curb appeal.

Settled patios and pool decks are perfect candidates, especially when water drainage issues threaten your foundation. Unstable steps become safe again with proper leveling, while garage floor settlement can be corrected before it leads to drainage problems or structural stress on garage walls.

Interior floor slabs in basements or utility rooms respond well to lifting, and AC pad leveling ensures your air conditioning unit functions efficiently without component strain. The key is having structurally sound concrete with minor to moderate settlement – typically a few inches rather than dramatic sinking.

When is Concrete Lifting Not the Right Solution?

Sometimes replacement or alternative repairs make more sense than lifting. Severely cracked or crumbling concrete presents the biggest limitation – if your concrete has fractured into many pieces or is actively deteriorating, there simply isn’t enough intact material to lift effectively. Existing cracks will remain after lifting and may even change size, requiring additional sealing.

If you’re looking to change your concrete’s appearance or texture, lifting won’t help. This method restores the existing slab to its original level without changing color, finish, or surface design. Want stamped concrete or a completely new look? You’ll need replacement.

Large tree roots causing significant localized lifting create complex situations where root removal might be necessary first. Major design changes like adding steps or expanding patios require new construction, not lifting.

Extreme settlement of 6-8 inches or more often indicates deeper problems requiring different solutions. Most importantly, if underlying foundation issues are causing the concrete settlement, addressing the foundation problem directly becomes the priority before considering cosmetic repairs.

For homeowners in the Texas Hill Country where challenging soil conditions are common, a thorough assessment by certified experts is essential. We’ll help determine if concrete lifting provides the right long-term solution for your specific situation, ensuring your investment delivers lasting results.

Why You Should Avoid DIY Concrete Lifting Foam

I’ve seen the YouTube videos. The Pinterest “hacks.” The online tutorials promising you can fix your sunken concrete with nothing more than a few cans of spray foam from the hardware store. As someone who’s been in the concrete lifting business for nearly two decades, I can tell you with absolute certainty: this is a terrible idea that will likely cost you far more in the long run.

The appeal is understandable. Canned spray foam costs about $5-10 per can, while professional concrete lifting might run hundreds or thousands of dollars. But here’s the reality: using insulation foam to lift concrete is like trying to jack up your car with a pool noodle. It’s simply not designed for the job.

Canned spray foam lacks the structural integrity needed to support concrete slabs. Professional geotechnical polyurethanes are engineered specifically for load-bearing applications, with compressive strengths exceeding 6,000 pounds per square foot. Your typical hardware store foam? It’s made for filling gaps around windows, not holding up thousands of pounds of concrete.

The expansion problem is where things get really messy. Professional foam injection requires precise control – we know exactly how much material to inject and can monitor the lift in real-time. Canned foam expands unpredictably, often continuing to grow for hours after application. I’ve seen DIY attempts where homeowners lifted their concrete so high it cracked neighboring slabs or created new trip hazards worse than the original problem.

Over-lifting is often irreversible without breaking up the concrete entirely. Once you’ve pushed a slab too high with uncontrolled foam, there’s usually no way to bring it back down to the correct level. What started as a $1,200 professional repair can quickly become a $5,000 replacement project.

Then there’s the moisture issue. Professional polyurethane foams are specifically formulated to handle the wet conditions commonly found under concrete slabs. Many DIY foams actually lose their effectiveness when exposed to moisture, leading to premature failure and the concrete settling again – sometimes even lower than before.

The safety risks can’t be overstated. Concrete slabs weigh thousands of pounds. When you start injecting material underneath them, they can shift unexpectedly. Professional technicians often saw-cut expansion joints to prevent slabs from binding together during the lifting process. Without this knowledge and proper equipment, you’re putting yourself at serious risk of crushing injuries.

I’ve also seen permanent staining from DIY foam attempts. The chemicals can cause yellow discoloration on concrete surfaces that’s impossible to remove. What was meant to be an invisible repair becomes a permanent eyesore.

The bottom line? Concrete lifting requires specialized equipment, professional-grade materials, and years of experience to do safely and effectively. When you’re ready for a solution that actually works, finding professional cement leveling near me is your best bet for lasting results that won’t create bigger problems down the road.

Conclusion

Concrete lifting has proven itself as a game-changer for homeowners dealing with sunken slabs. Instead of facing the expense, mess, and weeks-long disruption of concrete replacement, you now have a faster, more affordable solution that can restore your property’s safety and appearance in just hours.

Whether you choose the lightning-fast precision of polyurethane foam, the eco-friendly strength of stone slurry grout, or the budget-conscious reliability of traditional mudjacking, professional concrete lifting methods deliver results that last. Each approach has its sweet spot – foam for speed and waterproofing, stone slurry for environmental consciousness and strength, or mudjacking for maximum cost savings.

The beauty of this repair method lies in its versatility. From eliminating dangerous trip hazards on your sidewalk to restoring smooth driveways and level patios, concrete lifting addresses the problems that matter most to homeowners. You get your concrete back to level, your property looks great again, and you can actually use it within hours instead of waiting days for new concrete to cure.

Here’s the thing about DIY attempts – they’re just not worth the risk. We’ve seen too many homeowners try the spray foam route only to end up with cracked slabs, permanent stains, or concrete lifted so high it creates new problems. The science behind lifting heavy concrete safely requires professional equipment, specialized materials, and years of experience.

Living in the Texas Hill Country means dealing with challenging soil conditions that can cause settlement issues. Our clay-rich soils expand and contract with moisture changes, creating the perfect storm for concrete problems. That’s why having a local expert who understands these unique challenges makes all the difference.

At Total Foundation & Roofing, we’ve spent over 18 years helping homeowners throughout Kerrville, Fredericksburg, and the surrounding areas solve their concrete problems. We know which method works best for your specific situation, soil conditions, and budget. More importantly, we stand behind our work with solid warranties and the peace of mind that comes from certified, professional service.

Ready to get your concrete back to level? Don’t let sunken slabs continue to pose safety risks or hurt your property’s appearance. Explore our Concrete Leveling Services and request a free estimate today. We’ll assess your unique situation and recommend the best concrete lifting solution to get you back on solid, even ground.