Table of Contents

ToggleWhy That Small Crack in Your Concrete is a Big Deal

Patching cracks in concrete is essential preventative maintenance that protects your property’s structural integrity and value, not just a cosmetic fix. For fast, certified help custom to the Texas Hill Country, turn to our foundation and concrete repair experts for guidance and service options. Here’s what you need to know:

Quick Answer for Patching Cracks in Concrete:

- Clean the crack thoroughly using a wire brush and remove all debris.

- Choose the right filler: flexible sealant for cracks under 1/4-inch, cement-based compound for wider cracks.

- Prepare the surface by undercutting wider cracks into an inverted “V” shape.

- Apply the filler firmly, ensuring it penetrates deep into the crack.

- Smooth and cure according to product instructions before allowing traffic.

A cracked driveway or patio is more than an eyesore; it’s an open invitation for water to seep in, freeze, expand, and turn a minor issue into a major expense. Small cracks are gateways to bigger, more expensive problems.

The real danger is water seeping through cracks, which can undermine the subgrade, especially during Texas Hill Country’s freeze-thaw cycles. A hairline crack can evolve into a structural problem with uneven surfaces and trip hazards, requiring costly repairs that timely expert foundation and concrete services could have prevented.

Unrepaired cracks also invite weeds and create serious liability risks. Fortunately, most concrete crack repairs are straightforward DIY projects if you use the right techniques and materials.

I’m Daniel Sowell, owner of Total Foundation & Roofing Repair. With over 18 years of experience in the Texas Hill Country, I’ve seen how proper patching cracks in concrete saves homeowners thousands. This guide will show you how to assess, prepare, and repair concrete cracks correctly for a lasting fix.

Important patching cracks in concrete terms:

Understanding and Preparing for Concrete Crack Repair

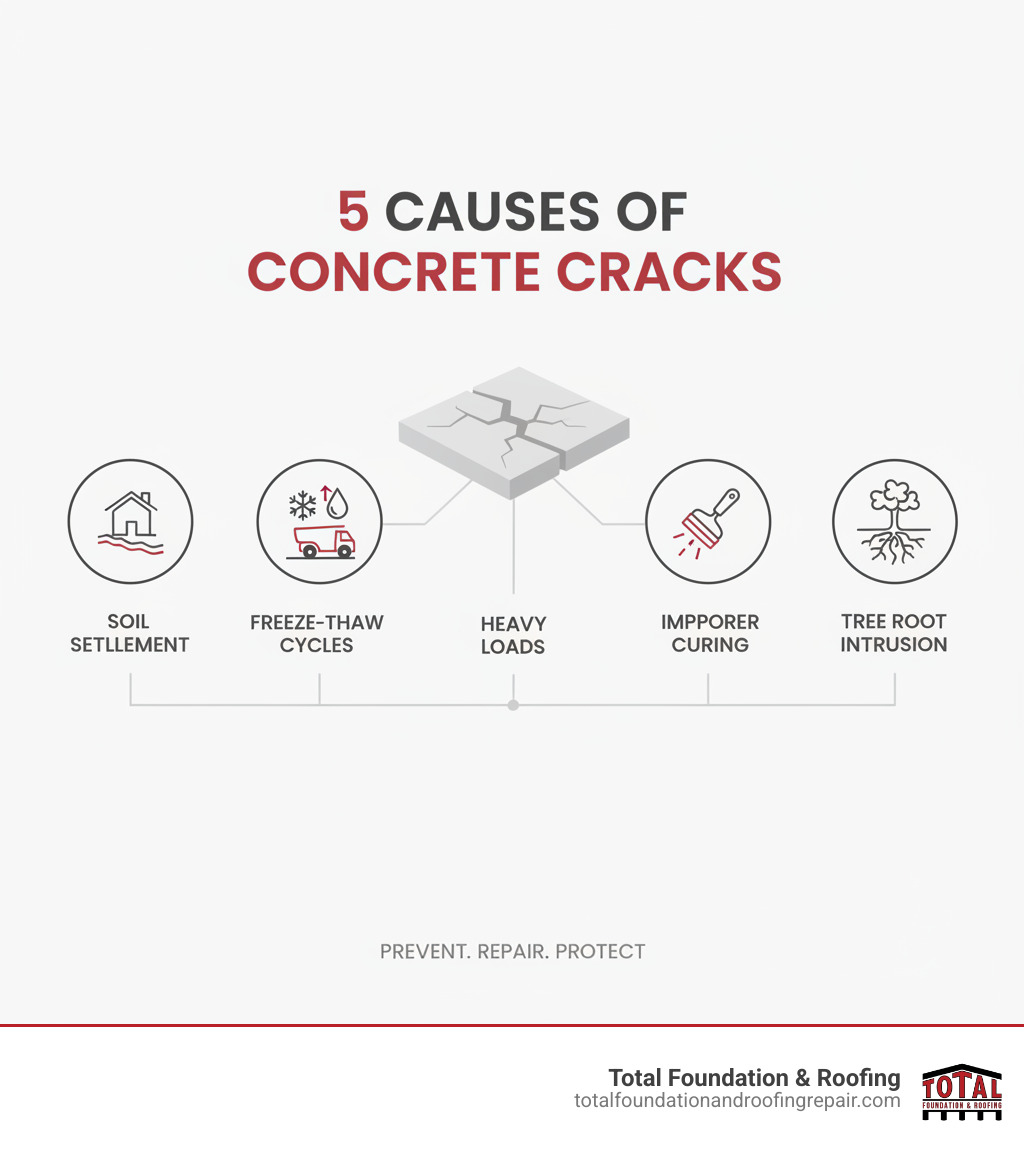

Understanding why a crack appeared is the first step to a proper fix. Concrete is stressed by ground settlement, temperature swings (especially Texas’s freeze-thaw cycles), heavy vehicles, and tree roots. Identifying the cause helps you choose the right repair method and prevent recurrence.

Why Prompt Concrete Crack Repair is Crucial

Ignoring a crack is a costly mistake. Here’s why prompt repair is non-negotiable:

- Water Damage: Water is concrete’s biggest enemy. It seeps into cracks, erodes the soil subgrade, and creates voids that lead to more cracking and settling.

- Freeze-Thaw Cycles: In areas like Kerrville and Fredericksburg, water in cracks freezes and expands with enough force to turn a small split into a major failure, potentially destroying a slab in a single winter.

- Safety and Aesthetics: Unrepaired cracks create dangerous trip hazards and allow weeds to grow, making your property look neglected.

- Foundation Issues: Cracks wider than 1/4 inch or with uneven sides can signal serious foundation settlement, which requires professional assessment. Industry leaders like the American Concrete Institute emphasize that timely repairs are essential for maintaining the long-term durability and safety of concrete structures.

- Financial Costs: Delaying repairs leads to exponentially higher costs. The rising cost of delaying repairs means a small patch job today can prevent thousands in replacement costs and higher concrete repair costs tomorrow.

Choosing the Right Concrete Crack Filler

Choosing the wrong filler means your repair will fail. The best product depends on the crack’s size, movement, and location.

- Flexible Sealants (Polyurethane/Silicone): These are your go-to for smaller, active cracks (under 1/4-inch) that expand and contract with temperature. They remain pliable, creating a durable, waterproof seal ideal for driveways and patios.

- Cementitious Patching Compounds: Use these for wider, stable cracks (over 1/4-inch). These rigid, cement-based products provide a strong fill that blends aesthetically with existing concrete but will crack again if the slab moves.

- Epoxy Injection: This is a professional solution for structural cracks in foundation walls or load-bearing slabs. Low-viscosity epoxy is injected deep into the crack, bonding the concrete to restore its structural integrity. This is not a DIY project for structural issues.

| Type of Filler | Best Use Cases | Flexibility | Cure Time | Pros | Cons |

|---|---|---|---|---|---|

| Flexible Sealants (Polyurethane/Silicone) | Narrow, active cracks (under 1/4-inch) that experience movement | High (expands/contracts with concrete) | Hours to days | Excellent water barrier; accommodates movement; easy DIY application; durable | Not for structural repair; can be tricky to tool smoothly; some discolor over time |

| Cementitious Patching | Wider, dormant cracks (over 1/4-inch) that are stable and not moving | Low (rigid, like concrete) | Days to weeks | Matches concrete aesthetically; provides strong, rigid fill; suitable for deeper repairs | Will crack if concrete moves; requires careful mixing; not ideal for active cracks |

| Epoxy Injection | Structural cracks (hairline to wide) in foundations, walls, or slabs | Low to Medium (depends on epoxy type) | Hours to days (for initial cure) | Restores structural integrity; excellent adhesion; prevents water; permanent solution | Requires specialized equipment; more expensive; not a DIY project for structural issues |

Always check manufacturer instructions for temperature and moisture requirements. Learn more about different concrete repair methods to choose the right approach.

How to Prepare the Surface for Patching Cracks in Concrete

Proper preparation is 80% of a successful repair. A patch on a poorly prepared surface will fail.

- Gather Tools and Safety Gear: You’ll need safety glasses, gloves, a wire brush, a hammer and cold chisel, a shop vacuum, and a pressure washer or stiff brush. For application, have a caulking gun, trowel, and mixing bucket ready.

- Clean the Crack: Vigorously scrub inside the crack with a wire brush to remove all dirt, debris, and vegetation. Use a shop vacuum to remove fine dust. For stubborn weeds, a special tool can help remove weeds.

- Remove Loose Concrete: Use a hammer and chisel to chip away any crumbling concrete along the edges until you reach a solid base.

- Undercut Wider Cracks: For cracks over 1/4-inch, chisel the edges to create an inverted “V” shape (wider at the bottom). This creates a mechanical lock that holds the patch in place.

- Clean the Entire Area: Pressure wash the crack and the surrounding concrete to remove any remaining dirt or contaminants that could prevent bonding. This is a vital step for any concrete driveway repair.

- Dry Completely: The surface must be completely dry before applying filler. Allow several hours or even overnight for drying after washing.

- Use Backer Rod: For cracks deeper than 1/2 inch, insert a foam backer rod. Push it about 1/4 to 1/2 inch below the surface. This saves filler material and allows the sealant to stretch properly.

The Step-by-Step Guide to Patching Cracks in Concrete

With a properly prepared surface, you can now fix the crack. The method depends on the crack’s size.

Repairing Narrow Cracks (Under 1/4-inch)

For hairline cracks up to 1/4-inch wide, a flexible, pourable sealant is the best choice, as it accommodates minor temperature-related movement.

- Prepare the Sealant: Cut the nozzle of the sealant tube at a 45-degree angle to an opening slightly smaller than the crack. Load it into a caulking gun.

- Apply the Sealant: Place the nozzle over the crack and apply a steady, even bead, forcing the material deep into the void. Avoid overfilling.

- Smooth the Finish: Immediately tool the bead with a putty knife or a wet, gloved finger to create a smooth, flush finish that adheres to both edges.

- Cure: Keep all traffic off the area until the sealant has fully cured according to the product’s instructions, which can take hours or days.

A Guide to Patching Wider Cracks in Concrete (Over 1/4-inch)

For stable cracks over 1/4-inch, a cement-based patching compound is ideal for most concrete slab repairs.

- Mix the Compound: Mix the powder with water to a thick, peanut butter-like consistency. Too much water weakens the patch.

- Dampen the Surface: Lightly mist the crack with water. This prevents the old concrete from drawing moisture from the new patch too quickly. The surface should be damp, not wet.

- Apply Bonding Adhesive (Optional): For deep patches (over 1/2 inch), brush a concrete bonding adhesive into the crack and let it get tacky before filling.

- Fill the Crack: Use a pointing trowel to firmly press the compound into the crack, ensuring it fills the undercut “V” shape. For deep repairs (1/2 to 2 inches), apply in layers.

- Finish the Surface: Overfill the crack slightly, then use a finishing trowel to smooth it flush with the surrounding concrete, feathering the edges.

- Cure Properly: Keep the patch moist for several days by misting it with water. This “moist-curing” is critical for developing full strength. Follow all manufacturer curing instructions.

When to Call a Professional (and How to Prevent Future Cracks)

While many cracks are DIY-friendly, some require professional expertise. Call a professional if you see:

- Cracks wider than 1/2 inch.

- Uneven cracks, where one side is higher than the other.

- Widespread or spiderweb cracking.

- Any crack in a foundation wall.

- Repaired cracks that reappear or new ones forming nearby.

These signs often point to serious underlying issues like expansive soil or significant settling. For homeowners in the Kerrville, TX, Fredericksburg, and Comfort areas, our team can accurately diagnose these complex problems with our professional crack repair services.

Don’t gamble with your property’s integrity. Request a comprehensive inspection and free estimate from our team.

Tips for Lasting Repairs and Prevention

To ensure your repair lasts and to prevent future cracks, follow these tips:

- Cleanliness is key: A successful patch starts with a perfectly clean crack.

- Choose materials wisely: Match the filler to the crack’s size and type (active vs. dormant).

- Follow instructions: Adhere to manufacturer guidelines for mixing, application, and curing.

- Mind the temperature: Repair when it’s above 50°F and out of direct sun.

- Cure correctly: Moist-curing is essential for cement-based patches.

- Ensure proper drainage to direct water away from concrete.

- Seal concrete every few years to protect against moisture.

- Manage tree roots and avoid parking heavy vehicles on residential driveways.

- Use sand instead of de-icing salts, which are known to damage concrete surfaces.