Table of Contents

ToggleWhy Colored Concrete Crack Filler Transforms Your Repair Results

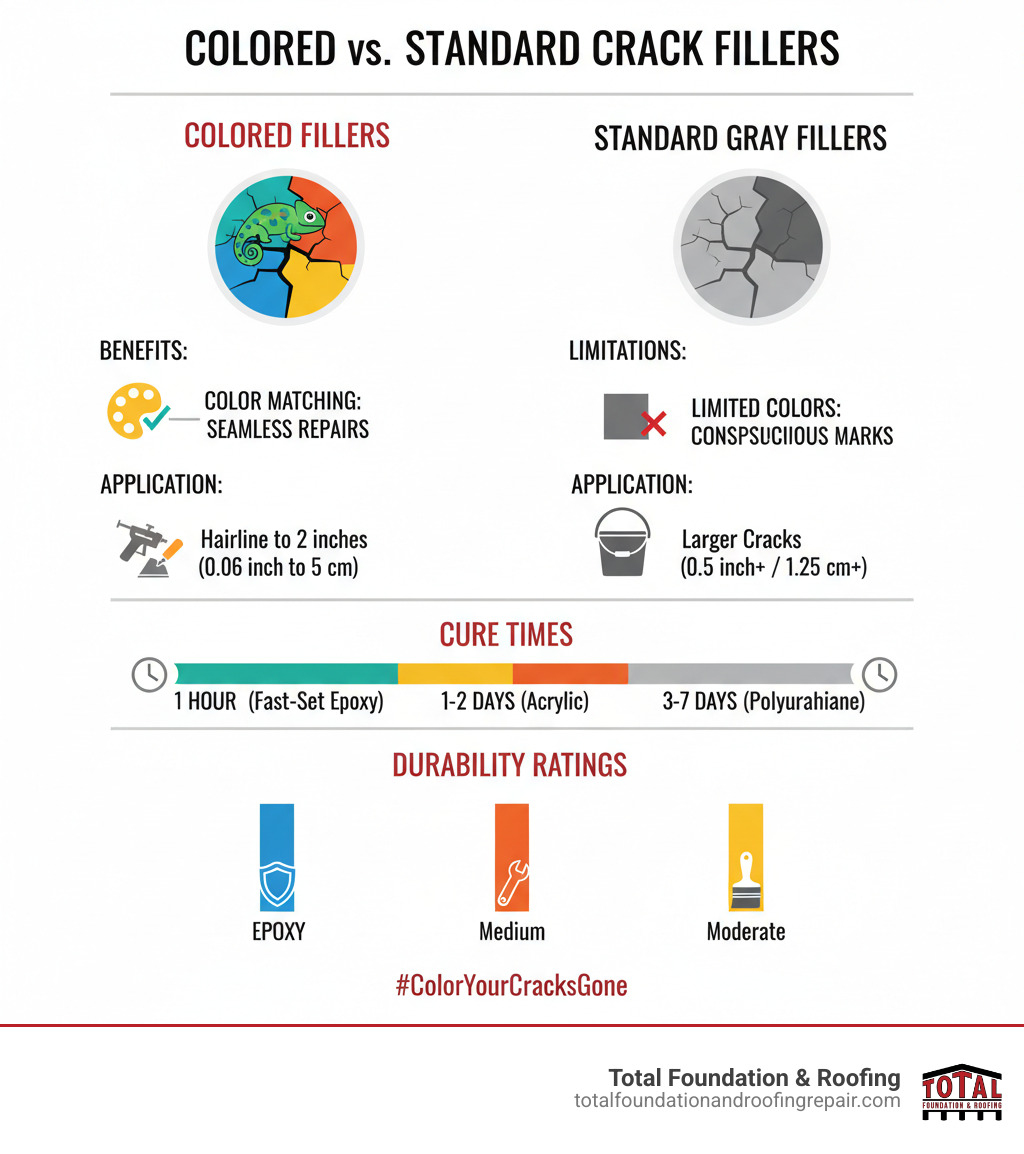

Colored concrete crack filler is the ideal solution for making concrete repairs disappear. Unlike traditional gray fillers that stand out on decorative surfaces, colored options can be mixed to match your existing concrete, preserving your property’s aesthetic. For homeowners in the Texas Hill Country, addressing cracks is vital to prevent water damage from freeze-thaw cycles. At Total Foundation & Roofing, we provide expert concrete repair services to restore both the function and beauty of your surfaces.

Top Colored Concrete Crack Filler Options:

- Epoxy-based fillers: Best for structural repairs and waterproofing.

- Polyurethane sealants: Ideal for flexible repairs on driveways and patios.

- Dry powder mixes: Water-activated, easy to apply, and available in 30+ colors.

- Acrylic fillers: Good for hairline cracks with a paintable finish.

Key Selection Factors:

- Match your crack width (hairline to 2 inches).

- Choose a color that matches your stained or stamped concrete.

- Consider weather resistance for outdoor use.

- Verify the cure time fits your project timeline.

Choosing the right product makes the difference between a repair that blends in and one that sticks out.

Colored concrete crack filler terms to remember:

A Comprehensive Guide to Choosing and Using Colored Concrete Crack Filler

This guide covers everything you need to know about colored concrete crack filler, from choosing the right type to advanced application techniques for a seamless, durable repair.

What is Colored Concrete Crack Filler and Why Use It?

Colored concrete crack filler is a specialized repair material designed to fill cracks while matching the color of your concrete. Unlike noticeable gray fillers, these are formulated with pigments for an integrated repair. The filler, typically a polymer-based compound like polyurethane, acrylic, or epoxy, bonds to the concrete, seals the crack, and prevents further damage.

Benefits of Using Colored Concrete Crack Filler:

- Seamless Aesthetic Repair: With over 30 pigment options available, you can achieve a repair that blends almost invisibly, maintaining your property’s curb appeal.

- Prevents Water Ingress: Fillers seal cracks to prevent water penetration, which is vital for avoiding freeze-thaw damage that can widen cracks.

- Minimizes Further Damage: Sealing cracks reduces erosion, weed growth, and debris accumulation.

- Durable and Long-Lasting: Many fillers, like industrial-strength epoxies such as Rust-Oleum Concrete Patch & Repair, provide a durable repair that can be stronger than the concrete itself.

- Cost-Effective: Repairing cracks is far more affordable than replacing an entire concrete surface.

For more insights, explore our comprehensive concrete crack solutions.

Types of Colored Concrete Crack Fillers on the Market

Selecting the right product depends on your specific needs for flexibility, strength, and cure time.

- Epoxy-Based Fillers: Known for exceptional strength, these are ideal for structural repairs and foundation cracks. Products like PC-Concrete Anchoring and Crack-Filling Epoxy offer a rigid, waterproof bond and can cure in as little as 4 hours.

- Polyurethane Sealants: Highly flexible and elastic, these are excellent for surfaces that expand and contract, like driveways and patios. Sikaflex Self-Leveling Sealant is a popular choice, offering superior weather resistance with a cure time of 3-7 days.

- Acrylic-Based Fillers: Easy to use and clean, these are great for DIY projects and hairline cracks. They are often paintable for further customization.

- Dry Powder Mixes (Cementitious): These water-activated powders, like Hairline Crack Fill Mix / Accent Enhancer, are versatile for custom tinting and filling small to medium cracks.

- Self-Leveling Fillers: Many polyurethane and epoxy fillers are self-leveling, creating a smooth surface on horizontal cracks without tooling. Loctite PL Self-Leveling Concrete Sealant is a good example.

- Flexible Rope-Like Fillers: Designed for large cracks and expansion joints, products like Crack Stix are melted with a heat torch to create a permanent, flexible seal.

Understanding these concrete repair methods is key to a successful project.

How to Choose the Right Color and Type

Choosing the correct filler involves assessing the concrete’s color, the crack’s size, and the location.

1. Color Matching:

- Use Samples: Never rely on a computer screen for color selection. Always start with physical samples.

- Custom Mix: Some dry powder products can be mixed to achieve custom shades for a perfect match.

- Test First: The final appearance can vary, and topcoats may darken the filler. Test in an inconspicuous area first.

2. Matching Filler to Crack Size:

- Hairline Cracks (up to 1/8″): Liquid fillers like BEHR PREMIUM® Concrete Crack Filler are ideal.

- Medium Cracks (1/8″ to 1″): Polyurethane, epoxy, and dry powder mixes work well.

- Large Cracks (over 1″): Substantial materials like Sashco Slab Concrete Crack Filler are needed. For deep cracks, use sand as a base filler.

- Foundation Cracks: Use specialized kits like the RadonSeal DIY Foundation Crack Repair Kit designed for waterproofing vertical surfaces.

3. Location and Environment:

- Horizontal vs. Vertical: Most fillers are for horizontal surfaces. Vertical cracks require non-slumping epoxies.

- Exterior vs. Interior: Exterior repairs need weather and UV resistance.

- High-Traffic Areas: Use high-strength epoxies for durability.

- Wet Areas: Use waterproof fillers or hydraulic cement like UGL Drylok Fast Plug for areas with constant moisture.

Table: Colored Concrete Crack Filler Types by Key Characteristics

| Filler Type | Ideal Crack Size | Cure Time (Approx.) | Flexibility | Strength | Key Benefit |

|---|---|---|---|---|---|

| Epoxy | Hairline to Large (1.5″) | 4-24 hours | Low | Very High | Structural repair, waterproofing |

| Polyurethane | Medium to Large (3″) | 3-7 days | High | High | Excellent flexibility, weather resistance |

| Acrylic | Hairline to Medium (1/2″) | 1-24 hours | Medium | Medium | Easy to use, paintable |

| Dry Powder Mix | Hairline to Medium (1″) | 1-24 hours | Medium | Medium | Water-activated, custom colors, accenting |

| Rope-Like (Melting) | Medium to Large (1/2″ to 1″) | 20 minutes | High | High | Permanent, flexible, fast traffic readiness |

For specific guidance, see our article on patching a concrete driveway.

The Application Process: A Step-by-Step Guide

Proper application ensures a durable, attractive repair.

1. Surface Preparation: The crack must be clean, dry, and free of debris. Use a wire brush to remove loose material, then rinse and allow it to dry completely. For deep cracks, use sand as a backer material, leaving about 1/4 inch for the filler.

2. Mixing and Application: Follow the manufacturer’s instructions. Pre-mixed products are ready to use, while epoxies and powders require mixing. Apply the filler using a caulk gun, squeeze bottle, or trowel, ensuring the crack is completely filled.

3. Level and Cure: Smooth the filler so it is level with the surrounding surface. Remove any excess material. Adhere strictly to the recommended curing time before exposing the area to traffic or moisture.

4. Safety Precautions: Always wear personal protective equipment (PPE), including safety glasses and gloves. Work in a well-ventilated area, especially with epoxy or solvent-based products. Read all safety labels before you begin.

For more details, see our complete guide to concrete slab repair.

Durability, Maintenance, and Common Pitfalls

The longevity of a repair depends on the product type, preparation, and environmental exposure.

- Durability: Epoxy and polyurethane fillers generally offer the longest-lasting repairs. However, concrete movement due to temperature changes or ground settlement can stress any filler over time.

- Maintenance: Expect to perform periodic touch-ups as part of normal concrete maintenance. Applying a quality concrete sealer over the entire surface can extend the repair’s life.

- Common Pitfalls:

- Imperfect Match: A perfect color and texture match can be difficult to achieve.

- Not for Structural Damage: Most fillers are cosmetic and do not fix underlying structural problems like an unstable slab.

- Curing Time: High-performance fillers can require up to a week to cure fully.

Understanding concrete repair costs can help you budget for your project.

Special Considerations for Stamped and Textured Concrete

Repairing stamped concrete requires matching both color and texture.

- Customize Texture: Use products that allow for the addition of sand aggregates to replicate the original texture.

- Application Technique: After applying the filler, use a stiff brush or sponge to stipple the surface, helping it blend with the surrounding pattern.

- Preserve Patterns: For cracks running through a pattern, you may need to carefully score the wet filler to re-establish the lines before it cures.

- Test First: Always test your color, texture, and technique in an inconspicuous area before tackling the main repair.

For significant unevenness in stamped concrete, our professional concrete leveling services offer a comprehensive solution.

When to Call a Professional for Your Concrete Repair Needs

While colored concrete crack filler is excellent for cosmetic fixes, it’s crucial to recognize when a DIY repair isn’t enough. Professional intervention is essential for the long-term safety and stability of your property in certain scenarios.

Signs You Need a Professional:

- Structural Cracks: Cracks wider than 1/4 inch, those with vertical displacement (one side is higher than the other), or cracks in load-bearing walls indicate a deeper problem.

- Large-Scale Damage: Widespread cracking or crumbling (spalling) points to issues beyond a simple patch, such as a poor sub-base.

- Uneven or Sinking Slabs: If your patio, driveway, or walkway is sinking or uneven, it requires professional techniques like concrete lifting or concrete leveling with foam injection to correct the underlying cause.

- Foundation Issues: Horizontal or stair-step cracks in foundation walls are serious red flags that demand an expert assessment and specialized foundation crack repair.

Total Foundation & Roofing: Your Partner in Concrete Health

At Total Foundation & Roofing, we understand the unique challenges of the Texas Hill Country’s climate and soil. For significant damage or structural concerns in Kerrville, TX, our professional team provides:

- Expert Assessment: We diagnose the root cause of concrete damage, not just the symptoms.

- Long-Term Solutions: We offer durable solutions, from advanced crack repair to comprehensive foundation repair services.

- Specialized Equipment: Our team is equipped for complex jobs like concrete lifting and leveling that are beyond the scope of DIY.

If you’re unsure whether your concrete issue is a simple fix or a sign of a larger problem, it’s always best to consult with experts to protect your home’s safety and value.