Table of Contents

ToggleWhy Foam Concrete Leveling Is Revolutionizing Home Repairs

Concrete leveling with foam injection is a modern repair method that uses expanding polyurethane foam to lift and stabilize sunken concrete slabs on driveways, sidewalks, and patios. If you’ve noticed uneven concrete creating trip hazards, you’re not alone. Sunken concrete is a common problem in Texas, but for homeowners dealing with these issues, professional concrete repair services offer a modern solution that’s faster and more durable than traditional methods.

Also known as polyjacking, the process involves drilling small 5/8-inch holes and injecting a lightweight polyurethane foam underneath. This foam expands, lifts the slab, and cures in as little as 15 minutes, allowing for immediate use. Unlike heavy mudjacking slurry, this material is waterproof and won’t wash away.

I’m Daniel Sowell, owner of Total Foundation & Roofing Repair. With over 18 years of experience helping Texas Hill Country homeowners, I’ve seen how concrete leveling with foam injection transforms damaged concrete into safe, stable surfaces that last for decades.

What is Foam Concrete Leveling and How Does It Work?

Foam concrete leveling, or polyjacking, is a precise method for fixing sunken concrete. If your driveway, sidewalk, or patio has dipped sections, it creates trip hazards and looks unsightly. Our goal is to restore these areas, making them safe and level again.

Understanding the Root Causes of Sunken Concrete

Concrete sinks not because of a flaw in the slab itself, but because of the ground beneath it. Here in the Texas Hill Country, we see a few common culprits:

- Soil Erosion: Water from poor drainage or leaks washes away soil from under the slab, creating voids that lead to sinking.

- Poor Compaction: If the ground wasn’t properly compacted during construction, the soil will settle over time, causing the concrete above to sink.

- Expansive Clay Soil: Common in Texas, this soil swells when wet and shrinks when dry. This movement creates voids and puts uneven pressure on concrete slabs. Understanding different types of soil is key to addressing this.

- Water Damage & Drought: Excessive moisture can soften the soil, reducing its ability to support the concrete. Conversely, drought can cause soil to shrink, leaving large gaps.

- Tree Roots: Growing roots can lift slabs, and decaying roots can leave voids, causing the concrete to settle unevenly.

For more insights into how these issues affect properties in our area, you can find more info about foundation repair in Kerrville.

The Polyurethane Foam Injection Process Explained

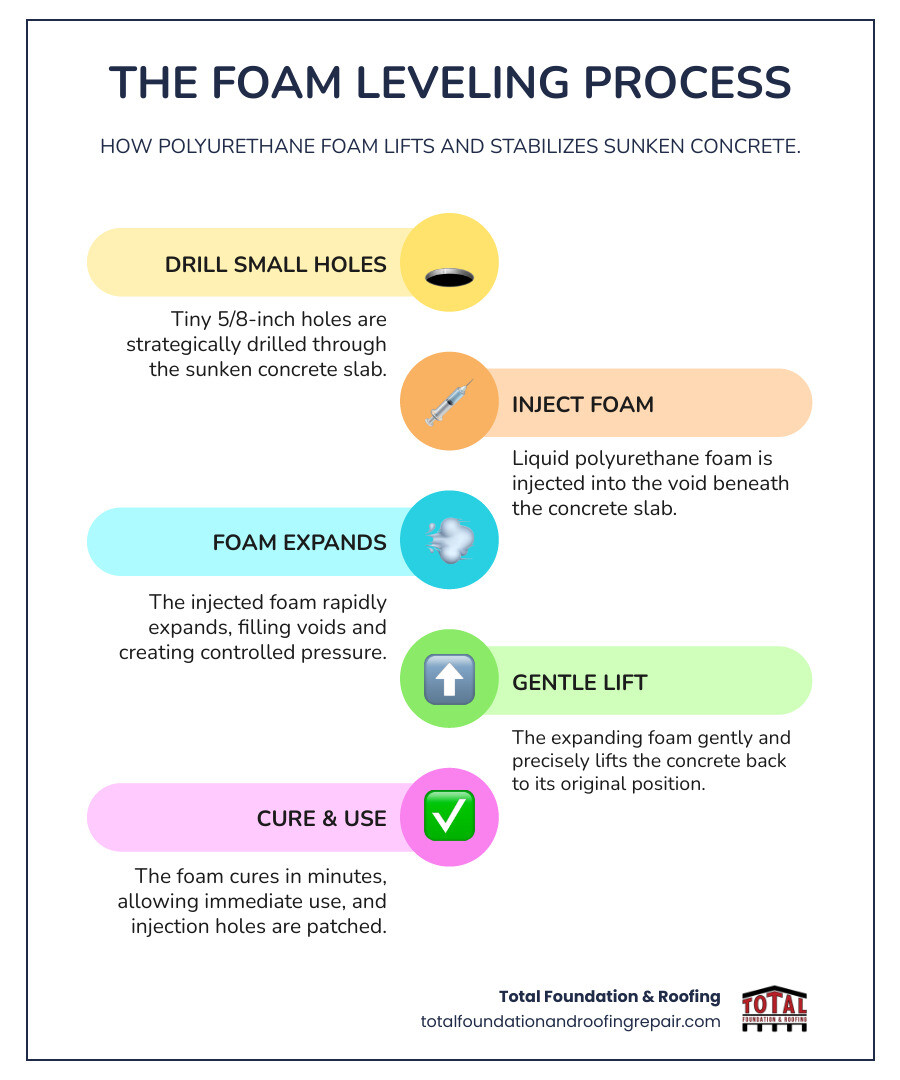

The beauty of concrete leveling with foam injection lies in its efficiency. After assessing the area, our technicians follow a simple process:

- Drilling Small Holes: We drill tiny, 5/8-inch holes (about the size of a dime) through the sunken slab. This minimizes the aesthetic impact.

- Injecting Liquid Foam: We inject a two-part liquid polyurethane foam through the holes using a high-pressure gun, ensuring it fills all voids.

- Expansion and Lifting: The foam components react and rapidly expand, compacting loose soil and gently lifting the slab back to its correct position.

- Rapid Curing: The foam solidifies within minutes. Most treated areas can be used almost immediately, though we recommend avoiding heavy traffic for a few hours.

- Patching and Cleanup: We patch the small injection holes with a matching compound and clean the work area, leaving your property tidy.

The entire process is minimally invasive and quick. For a visual guide, see How to Level Concrete Slabs Using Polyurethane Foam Injection. Our team uses top-tier Concrete Slab Lifting Equipment for precision and efficiency.

A Deep Dive into Concrete Leveling with Foam Injection

Concrete leveling with foam injection is a significant leap in repair technology. After nearly two decades in this business, I can say it has transformed how we approach sunken concrete, addressing the core weaknesses of traditional methods.

The secret is the high-density polyurethane foam. It’s inert, so it won’t react with soil, and it’s waterproof, so it won’t wash away. When we inject this foam, we’re not just filling a void; we’re creating a permanent, lightweight foundation that compacts the soil and lifts the slab, addressing both the symptom and the cause of settlement.

Key Advantages Over Traditional Methods like Mudjacking

For decades, mudjacking was the standard, but it had significant drawbacks. Foam injection solves nearly every one of its problems.

| Feature | Foam Injection (Polyjacking) | Mudjacking (Slabjacking with Grout) |

|---|---|---|

| Hole Size | Small (5/8-inch or dime-sized) | Large (1-5/8 to 2 inches) |

| Material Weight | Very lightweight (2.5-4 lbs/cu ft) | Heavy (100-108 lbs/cu ft) |

| Cure Time | Rapid (15 minutes – 1 hour) | Slow (hours to days) |

| Usability | Immediate | Hours to days |

| Invasiveness | Minimally invasive, cleaner | More invasive, messy |

| Water Resistance | Hydrophobic, waterproof, won’t wash out | Can wash away, susceptible to water |

| Durability | Long-lasting, stable | Can resettle due to heavy material |

The differences are stark. Foam weighs just 4 pounds per cubic foot compared to mudjacking’s 100+ pounds, meaning it won’t add stress that causes future settling. The smaller drill holes are less noticeable, and the rapid 15-minute cure time means you can use your driveway or patio almost immediately. Most importantly, the waterproof foam provides a permanent solution that won’t wash away. Learn more about this superior method in our guide on concrete lifting.

Disadvantages and Safety Concerns of concrete leveling with foam injection

While foam injection is an excellent solution, it’s important to understand its limitations:

- Higher Initial Cost: Foam leveling can cost more upfront than mudjacking. However, its durability often makes it more economical in the long run.

- Risk of Over-Lifting: The foam is powerful. An inexperienced technician can lift a slab too high, which is irreversible. Professional expertise is crucial.

- Cleanup Challenges: While cleaner than mudjacking, any foam that leaks onto the surface can be difficult to remove once cured.

- Environmental Concerns: Polyurethane is petroleum-based. While inert once cured, its production has an environmental footprint. The recycling rate for polyurethane materials is improving, with some foams now containing recycled content.

- When It’s Not Ideal: For massive voids or deep structural foundation problems, foam may not be the best solution. These issues might require more extensive repairs, like specialized foundation crack repair services.

Despite these points, the advantages of foam injection far outweigh the disadvantages for most applications.

Making the Right Decision for Your Property

Choosing the right concrete leveling method is a significant decision. Concrete leveling with foam injection offers remarkable longevity with minimal maintenance, but understanding its nuances is key to knowing if it’s the right fit for your home.

Cost, Durability, and Maintenance for concrete leveling with foam injection

Let’s talk about the long-term value.

The cost of concrete leveling with foam injection depends on the size of the area, the severity of the sinking, and site accessibility. While the initial investment may be higher than other methods, it’s almost always more economical than the messy and expensive process of tearing out and replacing the slab. For a detailed breakdown, see our guide on Concrete Lifting Cost.

As for durability, a professionally installed foam injection repair can last the lifespan of the concrete itself. The synthetic foam resists breaking down and won’t wash away, providing a stable base for decades.

Maintenance is minimal. Your main job is to manage water around the repaired area. Ensure downspouts direct water away from the slab and seal any joints or cracks with caulk to prevent water from getting underneath and causing new problems.

Common Myths vs. Reality: What to Expect

There’s a lot of information out there about concrete leveling with foam injection. Here’s the reality behind some common myths:

- Myth: Foam is bad for the environment.

- Reality: Once cured, polyurethane foam is inert and won’t leach chemicals. It also prevents old concrete from ending up in landfills. While petroleum-based, many modern foams include recycled materials.

- Myth: Foam is a magic bullet for wet conditions.

- Reality: While the foam itself is waterproof, the underlying cause of water intrusion (like poor drainage) must be fixed for a long-lasting repair.

- Myth: Foam perfectly fills every void.

- Reality: Foam is excellent at filling voids, but its expansion can be complex. The expertise of the installer is key to ensuring a complete and stable lift, especially with large voids.

- Myth: It’s a DIY project.

- Reality: Absolutely not. This process requires specialized equipment, training, and an understanding of soil mechanics. A DIY attempt can lead to permanent damage, like over-lifting the slab, which is irreversible.

At Total Foundation & Roofing, our Total Foundation & Roofing expertise means we understand these realities inside and out. We provide honest assessments and high-quality workmanship custom to the unique conditions of the Texas Hill Country. To see how we can help, learn More info about our Concrete Leveling Services.